Why Environmental Monitoring Isn’t Optional in Manufacturing

Imagine running a food processing line that makes ready-to-eat meals. One day, a customer gets sick. An investigation finds Listeria monocytogenes on a conveyor belt that hadn’t been cleaned in three days. No one thought to test it regularly. That’s not a hypothetical. It’s happened. And it costs businesses millions - not just in recalls, but in trust, lawsuits, and shutdowns.

Environmental monitoring isn’t about checking boxes. It’s about catching problems before they reach people. In manufacturing - whether you’re making medicine, baby food, or cosmetics - contamination doesn’t always come from raw materials. Often, it comes from the floor, the air, the drains, or even the sleeves of a worker. Testing for it isn’t optional. It’s the difference between staying open and closing down.

What Exactly Gets Tested? The Four Zones of Risk

Every facility that handles sensitive products uses a zone-based system to prioritize where to test. It’s simple: not all surfaces are created equal. The system breaks down areas into four zones based on how close they are to the product.

- Zone 1: Direct product contact surfaces. Think slicers, mixers, filling nozzles, packaging rollers. These are the highest risk. If something contaminates here, it goes straight into the product.

- Zone 2: Surfaces near product contact areas. Equipment housings, refrigeration units, nearby walls. Contamination here can easily spread to Zone 1.

- Zone 3: Areas close to production but not directly involved. Forklifts, storage racks, floor areas around machines. Surprising fact: in one study, floors accounted for 62% of all contamination events in labs.

- Zone 4: Remote areas - break rooms, hallways, entrances. Low risk, but still monitored to track how contamination spreads.

Here’s the catch: what one facility calls Zone 1, another might call Zone 2. That’s a problem. Consistency matters. If you don’t define your zones clearly, your testing won’t either.

How Do You Actually Test for Contamination?

Testing isn’t just swabbing surfaces and sending them off. Different contaminants need different tools.

- Microbial testing: Uses sponges or swabs to collect samples from surfaces. These go to a lab to grow bacteria. Results take 24 to 72 hours. That’s too slow for high-speed production lines.

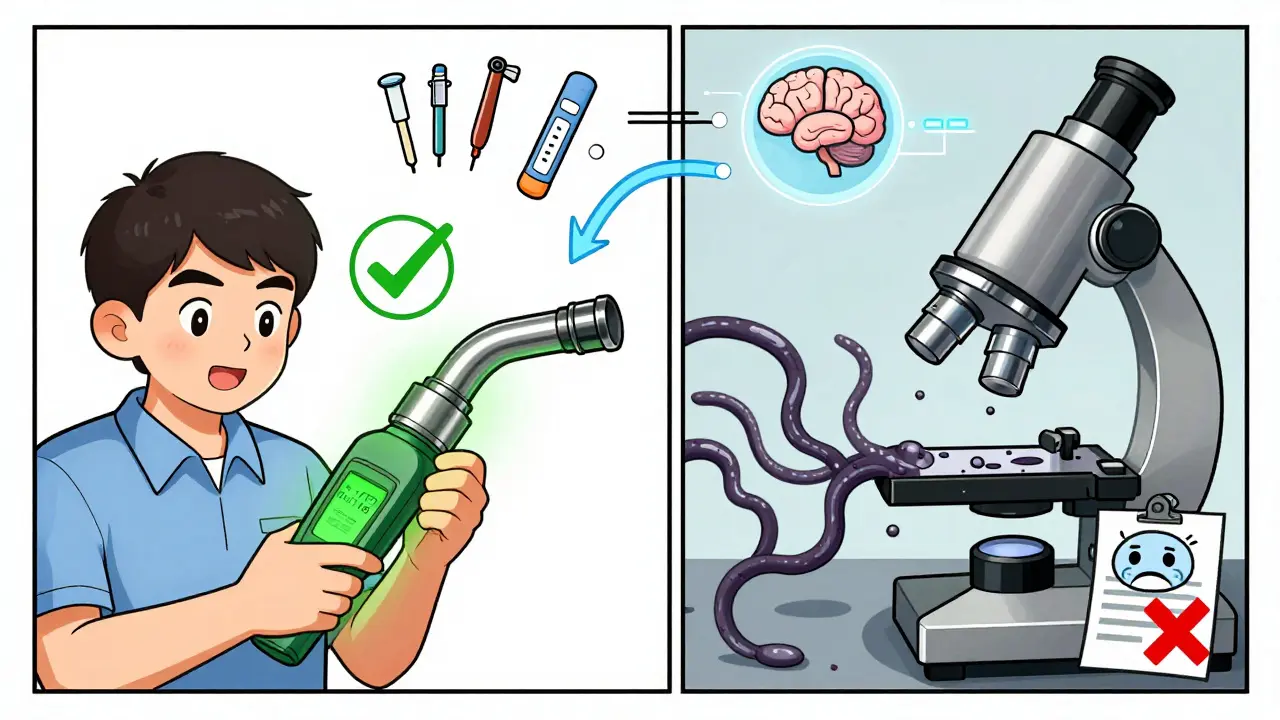

- ATP testing: Measures adenosine triphosphate - a molecule found in all living cells. A handheld device gives results in seconds. It doesn’t tell you what’s there, but it tells you if something is. Facilities using ATP see 32% faster turnaround between production runs.

- Air sampling: Uses liquid impingers or solid impactors to pull air through a device. Results are measured in colony-forming units per cubic meter (CFU/m³). Critical in pharmaceutical cleanrooms.

- Water testing: In pharma, purified water must meet USP <645> standards. Conductivity and total organic carbon (TOC) are checked continuously. In food plants, it’s about checking municipal water safety against EPA rules.

- Chemical and metal testing: Inductively Coupled Plasma (ICP) detects heavy metals. Chromatography (HPLC, GC) finds specific chemicals like cleaning residues.

Many facilities use ATP for quick checks and microbiological tests for confirmation. But too often, these systems run in silos. Data from ATP, allergen tests, and microbial results don’t talk to each other. That’s a major gap.

Regulations Vary by Industry - But the Goal Is the Same

Pharmaceuticals, food, and cosmetics all have different rules - but they all demand proof that contamination is under control.

- Pharma: Follows EU GMP Annex 1. Requires continuous air particle monitoring in ISO Class 5 (Grade B) cleanrooms. Temperature and humidity are tracked 24/7.

- Food: The FDA’s Food Safety Modernization Act (FSMA) and USDA’s Listeria Rule (9 CFR part 430) require aggressive testing for Listeria and Salmonella in Zone 1 and 2. RTE (ready-to-eat) facilities must test weekly.

- Cosmetics: Less strict than pharma, but still require microbial limits per ISO 22716. Contamination can trigger product recalls and brand damage.

What’s consistent? The FDA and EMA both say: environmental monitoring verifies control. If you can’t prove your environment is clean, you can’t prove your product is safe.

What Happens When You Don’t Do It Right?

It’s not just about fines. It’s about lives.

The CDC says 87% of foodborne outbreaks linked to environmental contamination could’ve been prevented. The USDA estimates foodborne illness costs the U.S. $77.7 billion a year. That’s not just hospitals and lost workdays. It’s families broken, brands destroyed.

Take the case of a Midwest meat processor. They didn’t test their floors regularly. A strain of Listeria built up in a drain. It spread to slicers. Three people died. The company shut down. Insurance didn’t cover it all.

Even small mistakes matter. A worker used a non-sterile swab to collect a sample. The swab itself introduced contamination. The lab reported a false positive. Production was halted for three days. The real problem? Training.

How Much Does It Cost - And Is It Worth It?

Medium-sized food plants spend $15,000 to $25,000 a year on environmental monitoring. That includes swabs, lab fees, training, and equipment. Two to three full-time staff are usually dedicated to it.

Pharmaceutical companies spend more - sometimes hundreds of thousands. But they also face higher stakes. A single contaminated batch of injectable medicine can trigger a global recall.

Here’s the math: a single recall can cost $10 million or more. The cost of testing? A fraction of that. And the cost of not testing? Loss of license, lawsuits, or worse.

ATP testing saves time. Real-time air monitors prevent shutdowns. AI-powered data systems predict contamination before it happens. These aren’t luxuries anymore - they’re necessities.

The Future Is Real-Time and Predictive

Environmental monitoring is changing fast.

Next-generation sequencing (NGS) can identify pathogens in under 24 hours instead of 72. AI analyzes years of data to spot patterns - like a spike in contamination every time a new shift starts. The European Medicines Agency now requires real-time data trending in pharmaceutical facilities. By 2027, 38% of monitoring systems will use AI, up from just 12% in 2022.

But technology alone won’t fix this. The biggest challenges remain: inconsistent zone classification, poor training, and data silos. The most successful facilities don’t just buy the best gear - they build a culture of accountability. Every employee knows why they’re swabbing, who’s responsible, and what happens if a limit is breached.

Getting Started: A Simple Checklist

If you’re new to environmental monitoring, here’s how to begin:

- Define your zones - clearly, with photos and maps. Get everyone to agree.

- Start with Zone 1 and Zone 2. Test daily or weekly. Don’t try to monitor everything at once.

- Use ATP for quick checks. Use lab tests for confirmation.

- Train staff. The FDA recommends 40 hours of hands-on training before anyone collects samples.

- Track everything. Use a digital system that links ATP, microbiological, and air data.

- Review results weekly. Look for trends, not just pass/fail.

- Update your plan every six months. Your facility changes. Your monitoring should too.

Environmental monitoring isn’t a department. It’s a mindset. It’s the quiet work done before the product is packed, before it’s shipped, before it’s sold. It’s the reason your customers don’t get sick. And in manufacturing, that’s worth more than any machine or software.

What is the main purpose of environmental monitoring in manufacturing?

The main purpose is to detect and prevent contamination before it affects products. By regularly testing surfaces, air, and water, facilities identify where microbes, chemicals, or particles are present and take action to stop them from reaching consumers. This protects public health and avoids costly recalls, shutdowns, or legal action.

Which surfaces should be tested most frequently?

Zone 1 surfaces - those that directly contact the product - should be tested most often, often daily or weekly. Zone 2 surfaces, which are nearby but not direct contact, are tested weekly to monthly. Zones 3 and 4 are tested less frequently, typically monthly or quarterly, but still matter because contamination can spread from them.

What’s the difference between ATP testing and microbiological testing?

ATP testing gives instant results by detecting a molecule found in all living cells. It tells you if something is dirty, but not what’s there. Microbiological testing takes 1-3 days but identifies specific organisms like Listeria or Salmonella. Most facilities use ATP for daily checks and microbiological tests for confirmation and regulatory compliance.

Why do pharmaceutical facilities have stricter environmental standards than food plants?

Pharmaceutical products, especially injectables, go directly into the bloodstream. Even tiny amounts of contamination can cause serious illness or death. Food products are generally processed to kill pathogens, but medicines are not. That’s why pharma requires continuous air monitoring, sterile environments, and stricter limits on microbial presence.

Can small manufacturers afford environmental monitoring?

Yes, but they need to start smart. Small facilities don’t need to test everything daily. Focus on Zone 1 and Zone 2 with basic swabs and ATP testers. Use third-party labs for confirmatory tests. Many regulators offer guidance for small businesses. The cost of not doing it - a recall or shutdown - is far higher than the cost of starting small.

What’s the biggest mistake facilities make in environmental monitoring?

The biggest mistake is treating it as a paperwork exercise. Many facilities collect samples but don’t act on the data. Others train staff poorly - using non-sterile swabs or mislabeling zones. The most successful programs treat environmental monitoring as a living system: data is reviewed, trends are analyzed, and actions are taken - fast.

Next Steps for Manufacturers

If you’re not doing environmental monitoring yet, start with Zone 1. Pick one critical surface - a filler nozzle, a slicer blade - and test it twice a week. Use ATP for speed. Get a lab to confirm results monthly. Train your team. Document everything. Then expand.

If you’re already doing it, ask: Are your zones clearly defined? Is your data being used to make decisions? Are you using technology to catch problems before they happen? If not, you’re just collecting dust - not preventing contamination.

Manufacturing quality isn’t just about the product. It’s about the environment that creates it. And that environment needs to be watched - every day, in every corner, with care.

Nancy Kou

This is the kind of post that makes you realize how much we take safety for granted. Every time I see a recall notice, I think about the people behind the scenes who are swabbing floors and checking drains while the rest of us eat our lunches without a second thought. It’s not glamorous work, but it’s the quiet backbone of everything we consume.

Dominic Suyo

Let’s be real - most of this is performative compliance dressed up as science. ATP testing? Great. But 80% of facilities use it as a magic bullet to avoid real cultural change. You can have the fanciest air monitors in the world and still have a worker sneeze into a Zone 1 nozzle because nobody’s holding them accountable. The system’s broken. The tech is just a bandage.

Adrienne Dagg

I work in pharma and I’m so tired of people acting like food plants are the only ones cutting corners. We had a batch of IV bags contaminated because someone reused a glove. Not because they were lazy - because they were overworked and undertrained. This isn’t about tech. It’s about respect. 🙏

bhushan telavane

In India, we don’t have the budget for ATP testers or AI systems. But we do have people who know their machines better than any sensor. My uncle works in a spice mill - he can smell contamination before the lab report. Sometimes old-school wisdom beats fancy gadgets.

Monte Pareek

You think Zone 3 is low risk? Try working in a plant where the forklift operator doesn’t wash his boots after a bathroom break. I’ve seen Listeria tracked from a hallway to a filling line because no one connected the dots. Monitoring isn’t about zones - it’s about behavior. Train people like their lives depend on it - because they do.

Matt Davies

This is why I love engineering. It’s not just about making things - it’s about making sure they don’t kill people. I used to think contamination was some distant corporate nightmare. Then I ate a sandwich from a plant that got shut down. That’s when it hit me: every bite is a gamble. And someone, somewhere, is trying to make sure that gamble isn’t lethal.

Hussien SLeiman

I’ve read this entire thing and I still don’t believe any of it. You say Zone 1 is critical? Then why do 90% of outbreaks trace back to Zone 4? You’re all chasing ghosts. The real problem is that manufacturers don’t want to admit their supply chains are contaminated before it even hits the plant. You’re testing the wrong things. You’re testing the symptoms, not the source. And no, ATP doesn’t fix that. It just makes you feel better while the rot spreads.

benchidelle rivera

To everyone saying this is too expensive: You’re not thinking about the cost of silence. A single recall doesn’t just cost money - it costs sleep. It costs trust. It costs the future of your team. I’ve seen workers cry when their plant closes because they knew they’d never find another job like it. This isn’t a line item. It’s a lifeline. Start small. Start now. Don’t wait for someone to die before you act.

holly Sinclair

I keep thinking about the philosophical weight of this. We’ve built entire systems to measure the invisible - microbes, chemicals, airborne particles - because we’ve learned that what we can’t see can kill us. But we still don’t measure the human cost of ignoring it. The fear. The shame. The silence of families who never get answers. Is environmental monitoring about science? Or is it about finally admitting that we are not above nature - just temporarily better at hiding from it?

Kelly Mulder

The FDA’s guidelines are laughably outdated. They still reference 1990s protocols while the rest of the world has moved to real-time genomic sequencing. And yet, we’re still using swabs and paper logs? This isn’t compliance - it’s archaic theater. If you’re not using NGS and AI-driven predictive analytics by 2025, you’re not a manufacturer - you’re a museum exhibit.

Chris Davidson

Zone classification is inconsistent because no one cares enough to standardize it. Every facility reinvents the wheel. The industry needs a universal zone taxonomy. Not a suggestion. A mandate. And if you don’t comply you lose your license. Simple.

Anna Sedervay

I’ve been told that environmental monitoring is just about safety. But what if it’s really about control? Who benefits when we’re all obsessing over swabs and ATP readings? The equipment vendors. The consultants. The labs. Meanwhile, the workers who actually do the swabbing? They’re paid minimum wage and told to stay quiet. This isn’t science. It’s surveillance disguised as safety.